Brian Visits the Brotherwood Factory

Back when Mum and Dad first started researching the idea of a Brotherwood WAV, Dad couldn’t get into their car. So, when it came to a showroom visit, Mum went with my sister, Helen, instead. On their return, they were so full of enthusiasm about what they’d seen that Dad said to me, “I can’t believe it’s really as interesting as they’re making out!”

Now Dad has his own Brotherwood WAV, he decided he wanted to visit their showroom and see for himself. As it was a lovely day, Mum decided to stay at home for some peace and quiet in the garden.

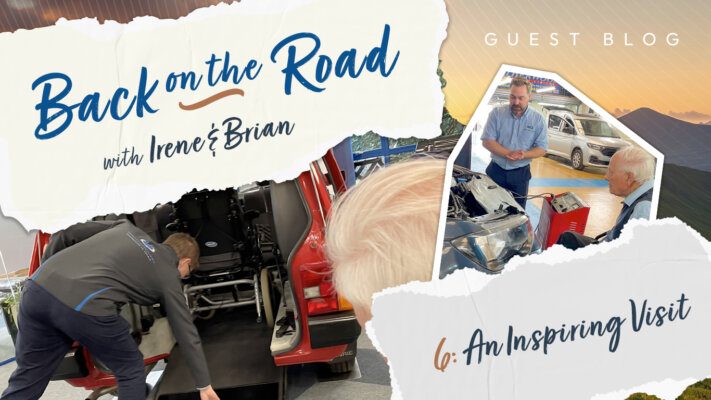

We were met by Jo on reception, and Marcus (Mobility Consultant) and James (Marketing Manager) showed us around. The first vehicle we saw was an impressive Mercedes-Benz V-Class. James explained that their research and development department are always on the lookout for new makes and models to convert, so they can offer customers as much choice on size, style, and price as possible. Dad wondered if there might be an option for a Jaguar or Rolls Royce WAV in the future?!

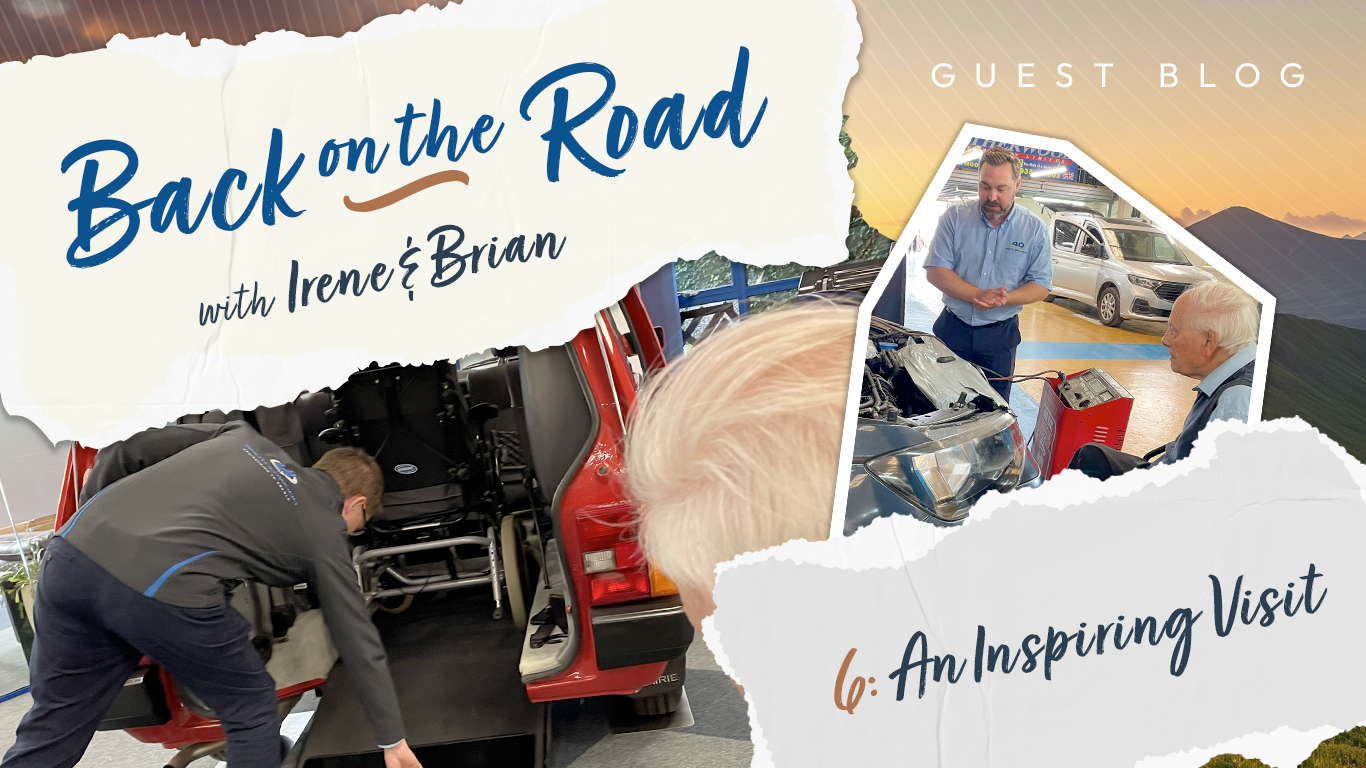

The V-Class was at the beginning of its conversion journey, and was having parts stripped out. Marcus told us this is done with painstaking care, to preserve as much as possible for reuse. The parts are all logged and stored, ready to be replaced at the end of the process.

From the outside of the showroom, you would have no idea how much of a labyrinth it is inside. Here, almost all the conversion parts are designed and machined on site before being tested in a “clean room” for quality control. There’s even a room full of different nuts, bolts, screws and so on, which are used to put together a “build kit” for each conversion.

Onto yet another area where the WAVs have their floors lowered, and specially machined profiles are bolted, welded and bonded into place under infrared light.

Next of course, there’s the famous PAWRS system. It’s Brotherwood’s own patented design and the only device that acts as both a winch and a restraint. As well as being used in Brotherwood’s own conversions, they’re also shipped all over the world.

Conversion complete, the WAVs go back to be trimmed, and everything is put back in. We joked that it’s not like building flatpack furniture – at Brotherwood they never end up with one too many or one too few parts!

Attention to detail is everything here. Even down to re-spraying paintwork in one of their two booths, and the very thorough valet each vehicle has before it leaves the building.

Back in the reception, Dad inspected the first ever Brotherwood WAV, built in 1985. We wondered how many lives had been changed by their vehicles since then.

Everyone at Brotherwood is so passionate about what they do. Even the founder, Rod, who is semi-retired, was upstairs when we visited. “We’re not sure why he’s here today,” joked James, “But we can’t keep him away!”

Before we left, James and Marcus helped Dad with a few questions he had about his WAV and reminded him that he can call them anytime. You really couldn’t ask for better aftercare service.

On the way home, Dad reflected that Mum and Helen were right to be so enthusiastic about their visit to the showroom. “It really is incredible what they do there,” he said.

Next time, Next time, the Brotherwood WAV helps Dad take a trip down memory lane…

About this Blog

‘Back on the Road’ follows how a Brotherwood Volkswagen Caddy Wheelchair Accessible Vehicle (WAV) is changing the lives of Somerset residents, Irene and Brian.

Brian is a wheelchair user and the couple are 80-something-young. They have a Golden Retriever, Barnaby, who will sadly never experience the adventures a Brotherwood WAV makes possible, as he refuses to travel by car.

The blog is written by one of their daughters, and will bring regular updates of how they are rediscovering the joys of spontaneous travel thanks to Brotherwood.