ENGINEERING TO ENABLE

Brotherwood® WAV Conversion Process

Brotherwood® Wheelchair Accessible Vehicles go through several crucial processes under the hands of our skilled engineers, to create the highest quality accessible cars.

Every Wheelchair Accessible Vehicle we produce undergoes our detailed transformation, to meet our exacting standards for quality, comfort, inclusion and safety – a process we call Engineering to Enable.

Brotherwood® WAV Conversion Process

How are Cars Made Wheelchair Accessible?

Brotherwood Wheelchair Accessible Vehicles are engineered to meet our exacting standards for quality, safety and conformity.

- We start by removing the original passenger seats, interior trim and carpet from the vehicle. [0:26]

- The underside of the vehicle is also stripped, removing the original fuel tank and exhaust. [0:32]

- Next, the rear suspension assembly is dismantled, including the brakes and brake lines, prop shaft and differential. [0:36]

- The vehicle is now a bare bodyshell, ready for conversion. [0:45]

- A prescribed section of the floor is cut away, leaving a large void in the vehicle chassis. [0:52]

- A flat, level, lowered floor section is then welded into place, corrosion treated and undersealed. [0:58]

- Custom-made rear passenger seats are now installed, and the interior is upholstered and carpeted to match the original vehicle trim. [1:04]

- A Power Assisted Wheelchair Restraint System is also installed. [1:09]

- The rear suspension assembly, prop shaft and differential can now be re-instated. [1:17]

- A modified exhaust system and custom-made, low profile fuel tank also replace the original components. [1:26]

- Finally the powered rear access ramp is installed, enabling the wheelchair user to travel in the centre of the vehicle, inclusively with the other passengers. [1:28]

- The wheelchair is secured by a safety-tested 4-point restraint system. The lowered floor provides a lower centre of gravity, more headroom and better visibility out of the windows. [1:37]

- The Brotherwood conversion blends discretely with the original vehicle, leaving you to enjoy the journey. [1:52]

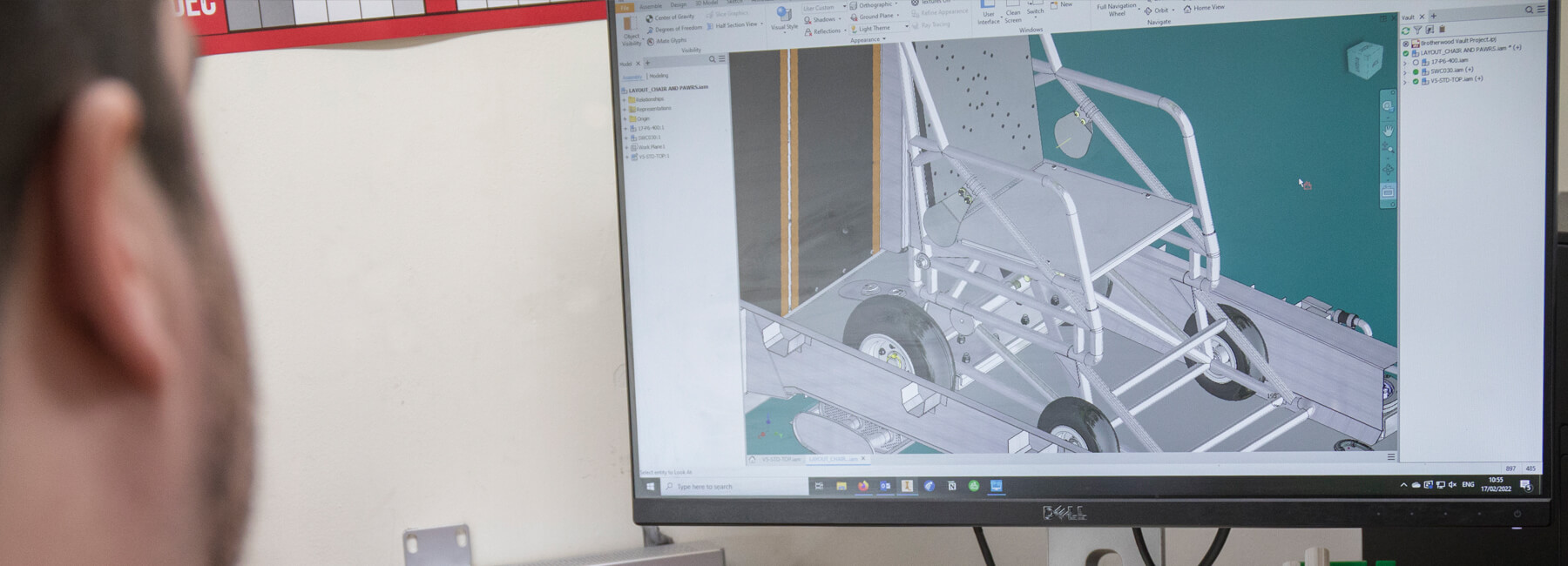

Unique Design

Brotherwood WAVs are developed in-house by our team of designers – using design principles refined over almost 4 decades of experience in WAV manufacturing.

Quality Engineering

Our ISO:9001 approved engineering process ensures that every Brotherwood WAV meets the highest standards for build quality, compliance and conformity.

Finished by Hand

Brotherwood WAVs are hand finished by our expert engineers to an industry leading standard. Using materials matched to the original interior creates a seamless finish.